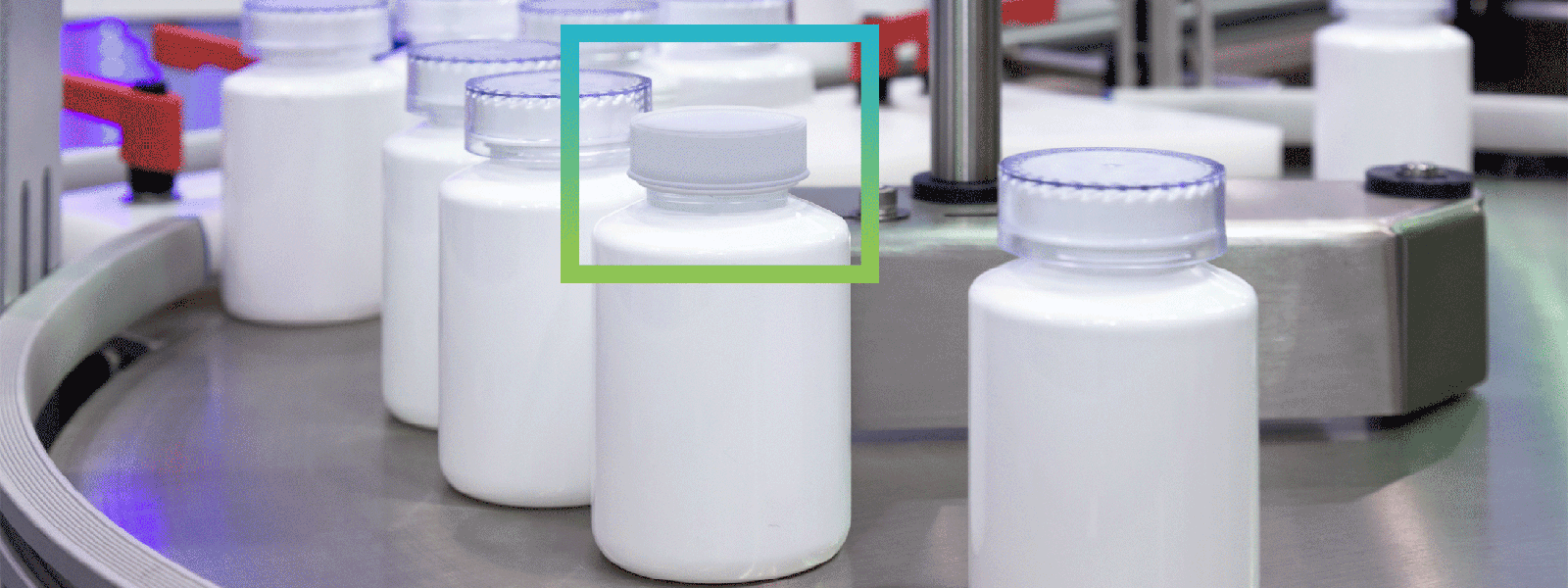

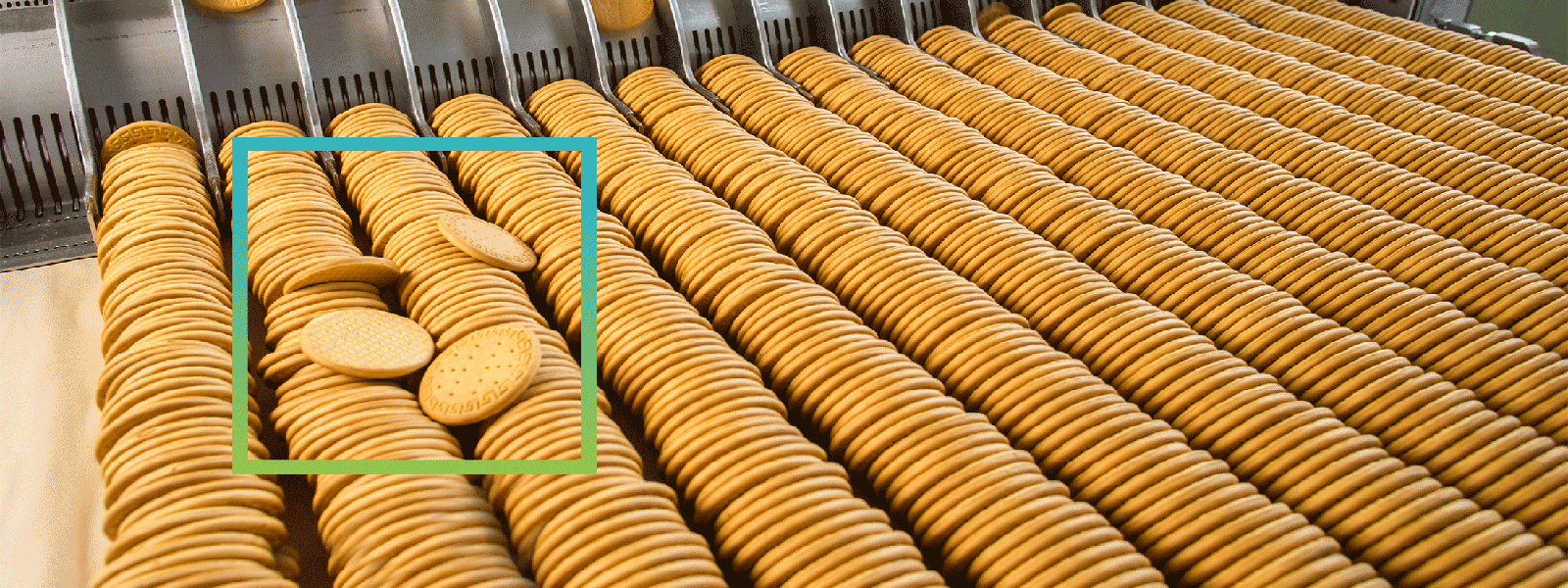

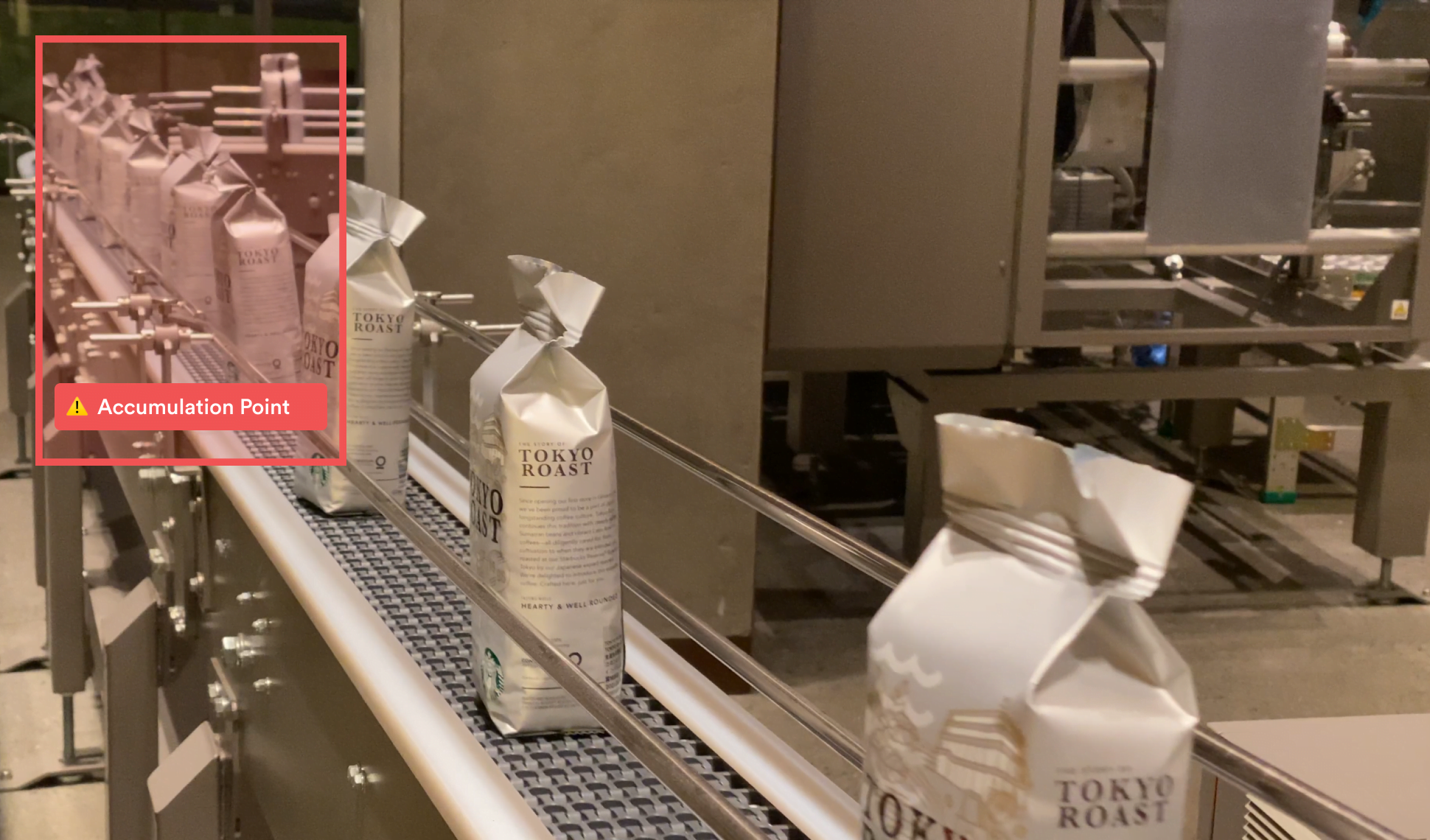

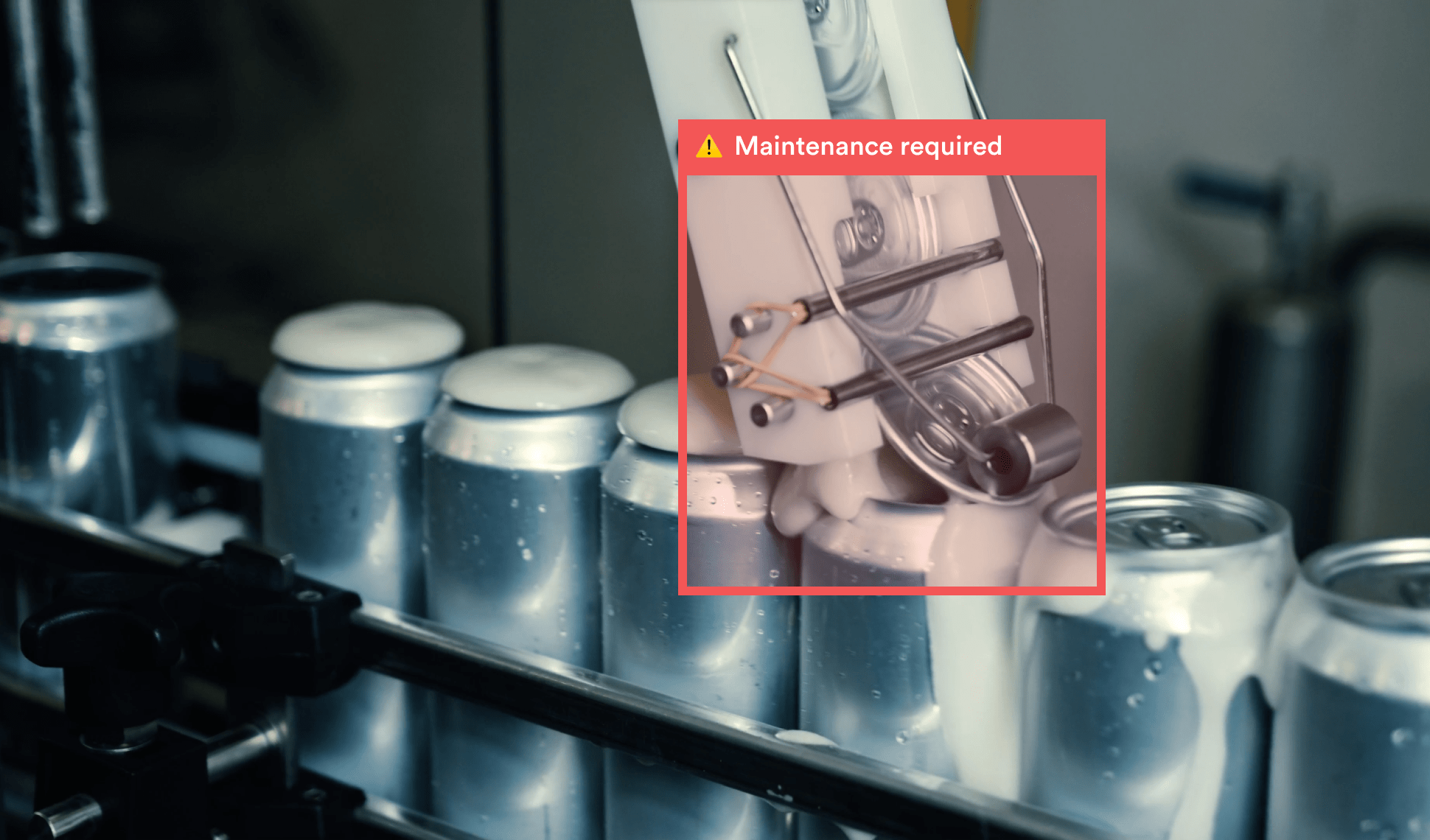

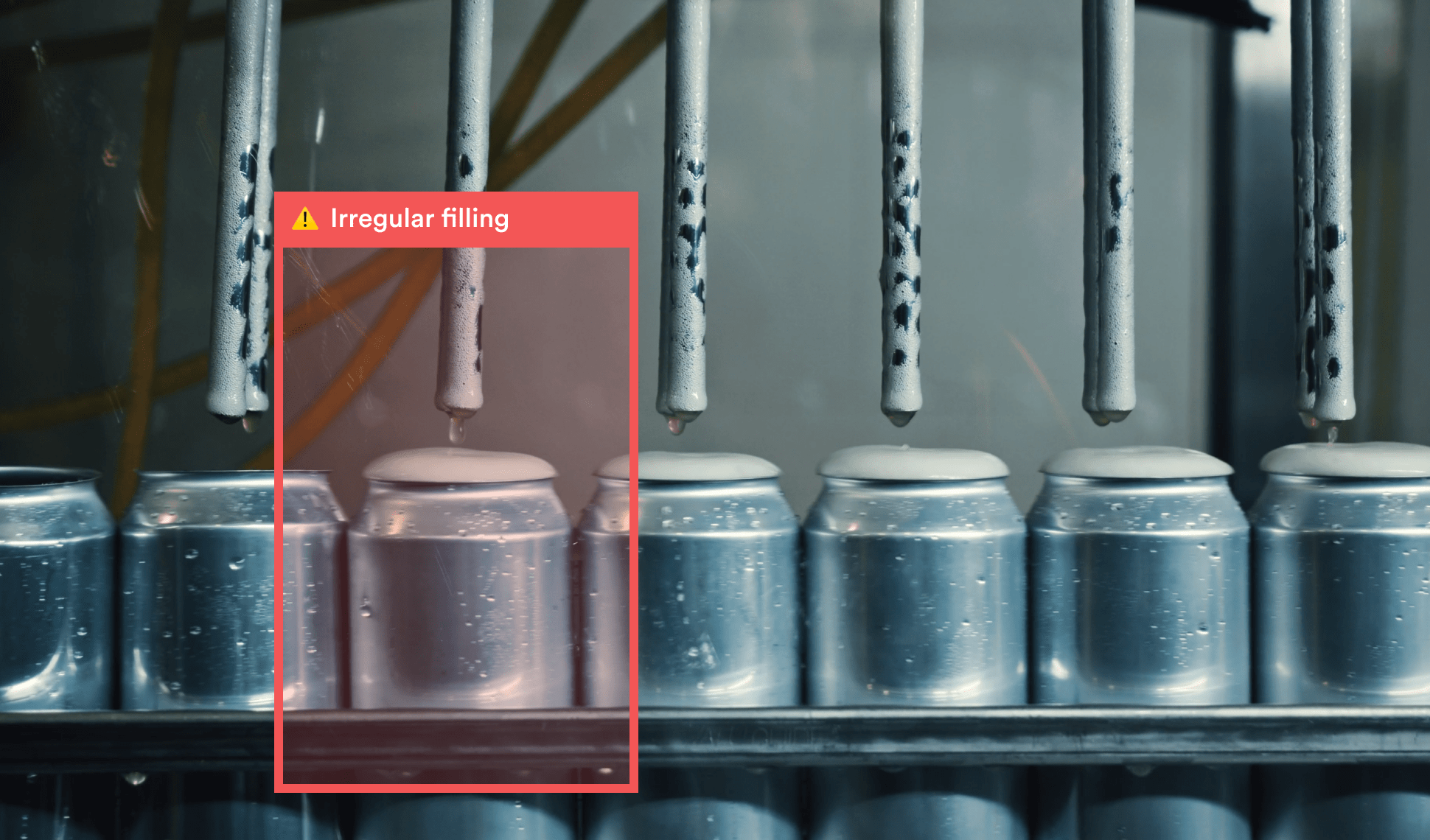

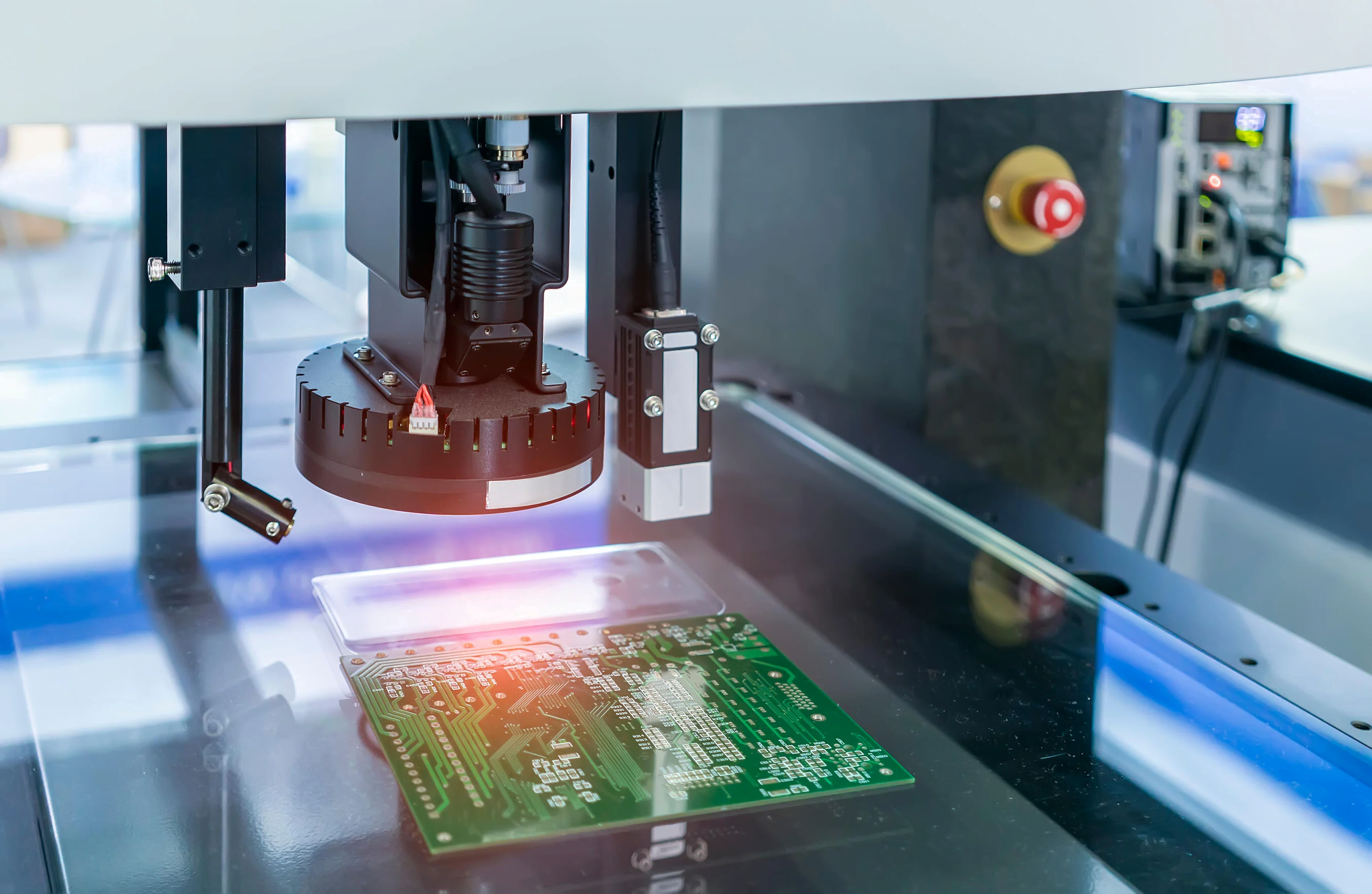

Vision AI for Industrial Inspections

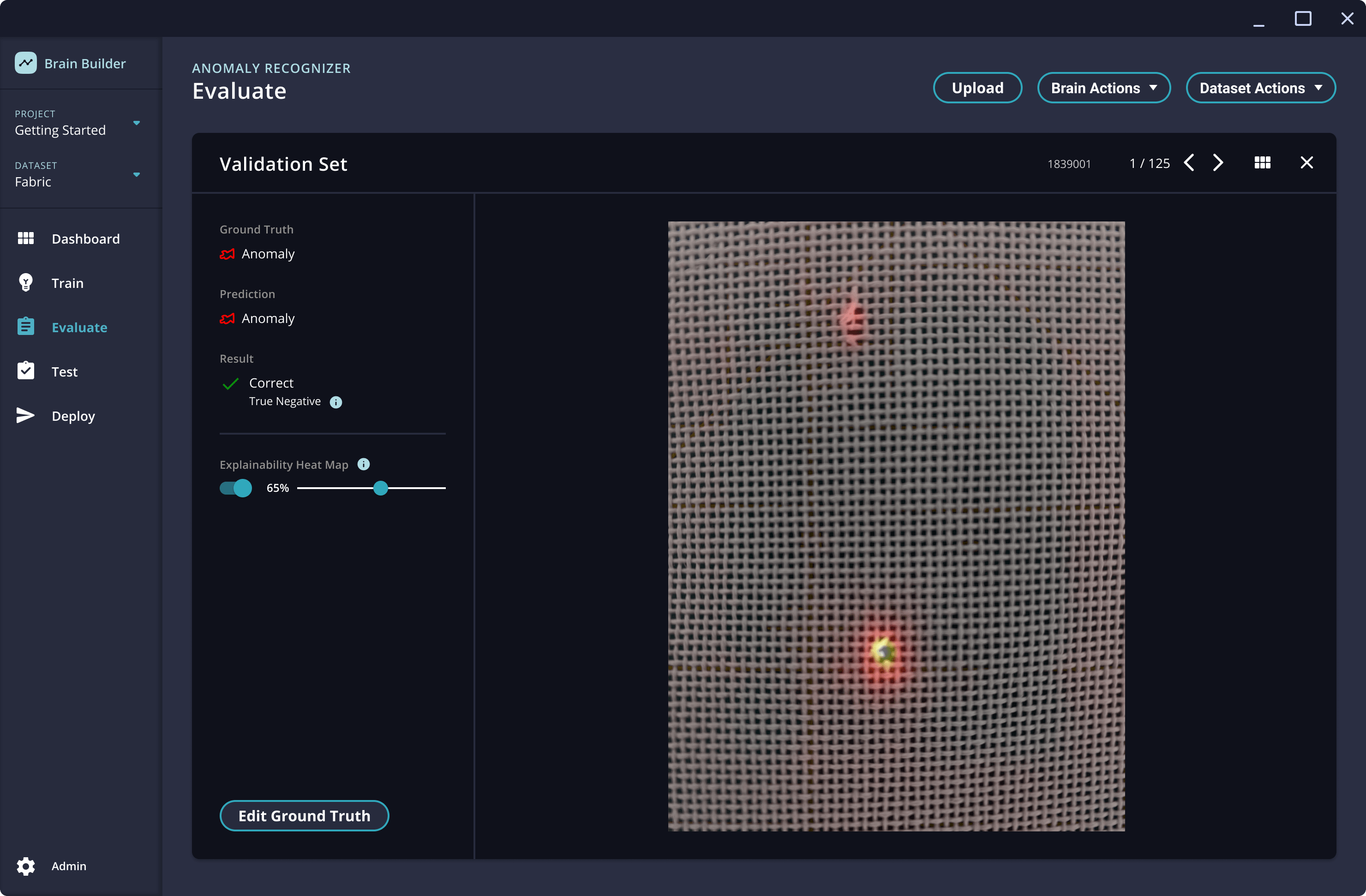

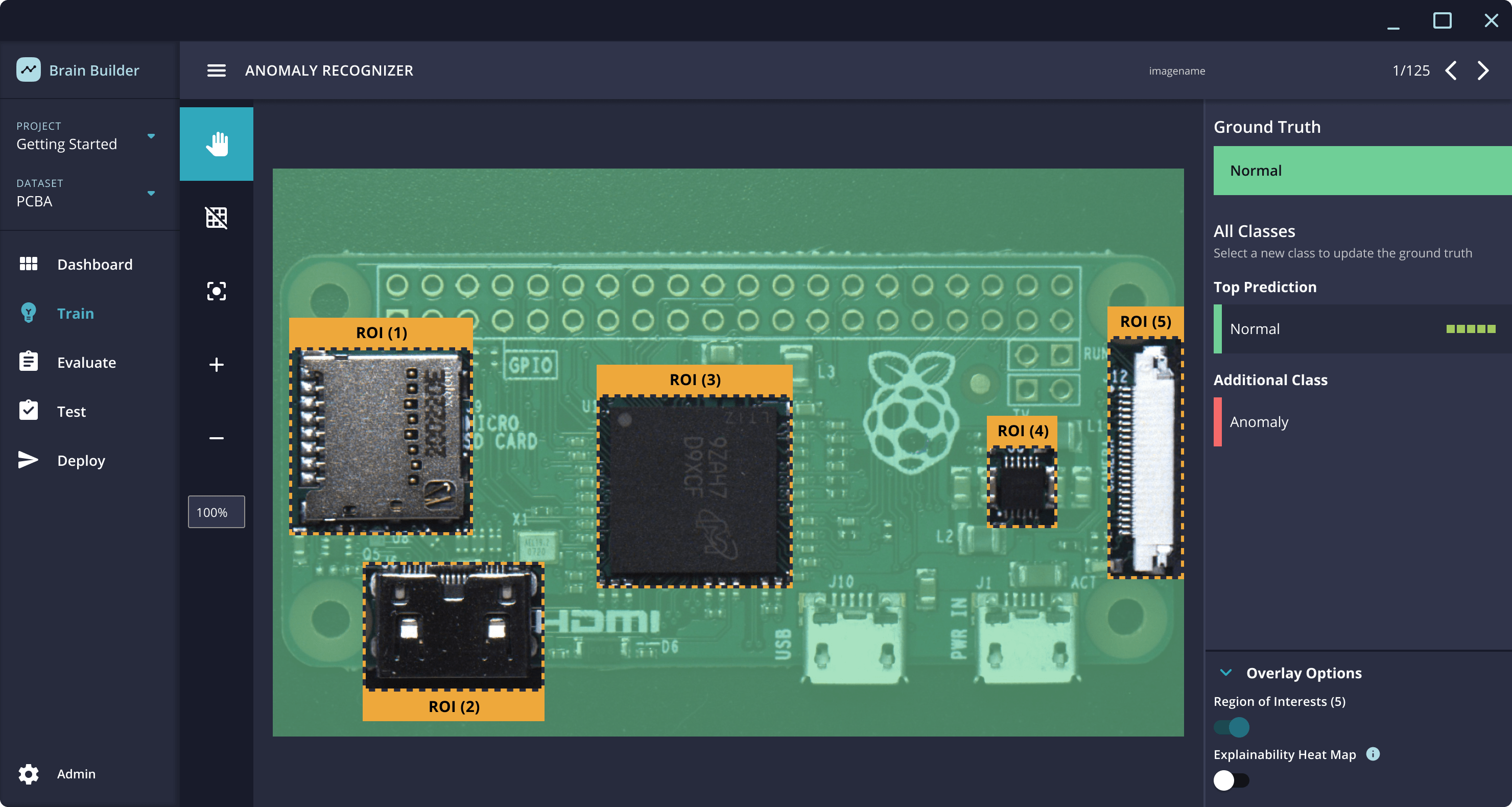

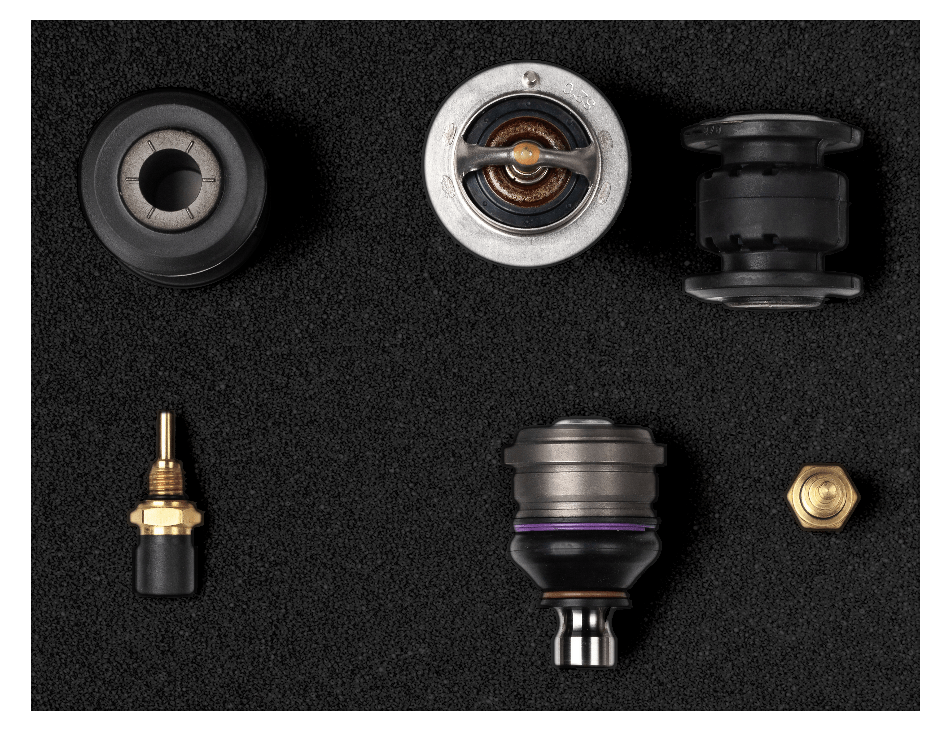

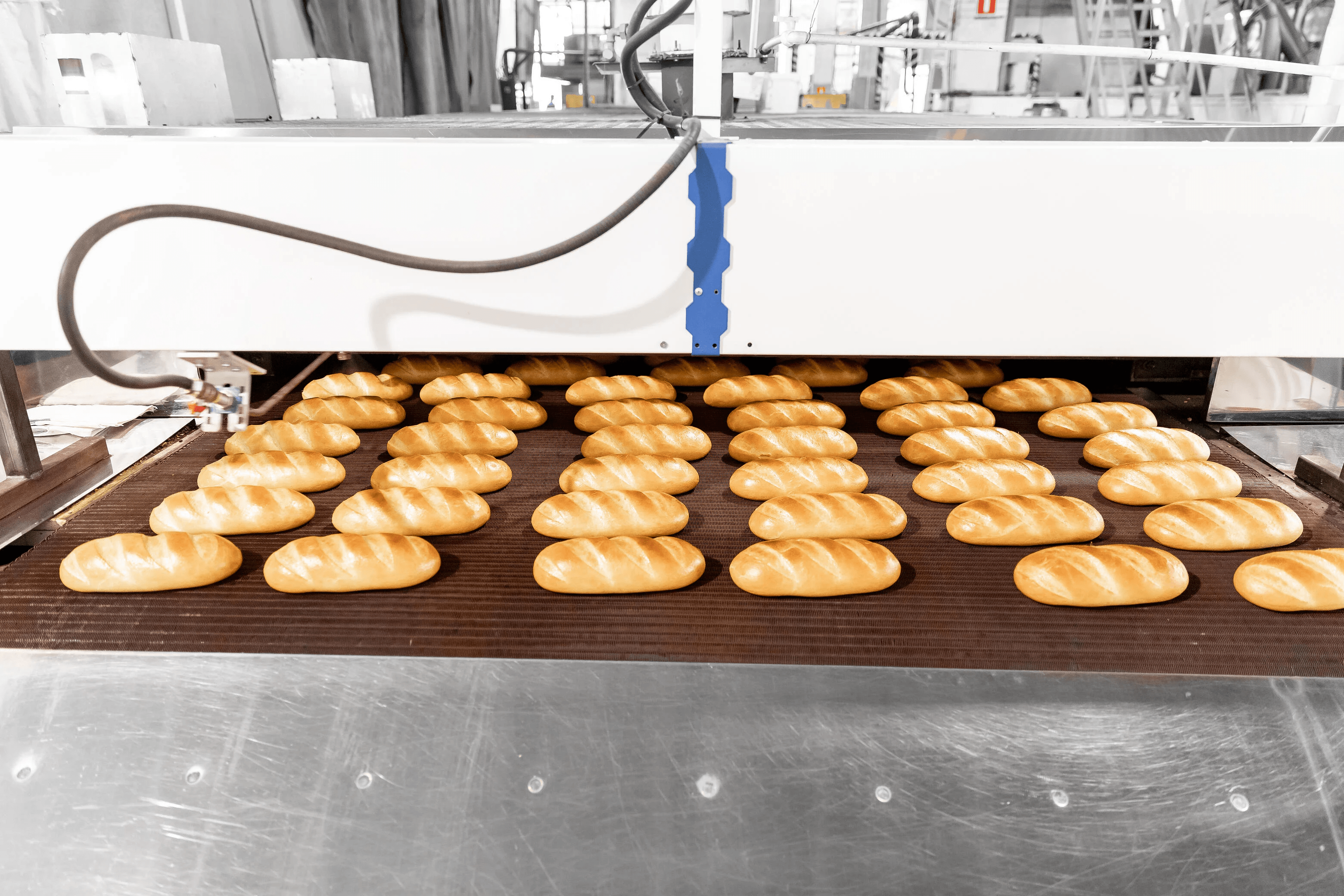

DEEPQ is on a mission to help manufacturers improve their vision inspection process. Supply chain issues, labor shortages, and the risk of recalls are driving the need for more automation. Our Visual Inspection Automation (VIA) software goes beyond the capabilities of traditional machine vision in detecting anomalies and defects, even when products have natural variations. Using our proven vision AI technology, manufacturers can scale production, reduce waste and adapt to workforce changes, while achieving even higher levels of quality control.