Our Machine Vision experts develop, build, and support machines and systems for optical inspection and process control in close cooperation with our nine locations worldwide. Our scalable, adaptive solutions have a high degree of standardization. They can therefore be used in the laboratory, in small series and single part production as well as in production lines with short cycle times. This allows us to get the most use out of each application with the minimum investment needed. A close and trusting partnership with our customers is a matter of course for us.

Benefits at a glance

Innovative Imaging Solutions

Artificial Intelligence integrated

Seamless Integration in Machinery

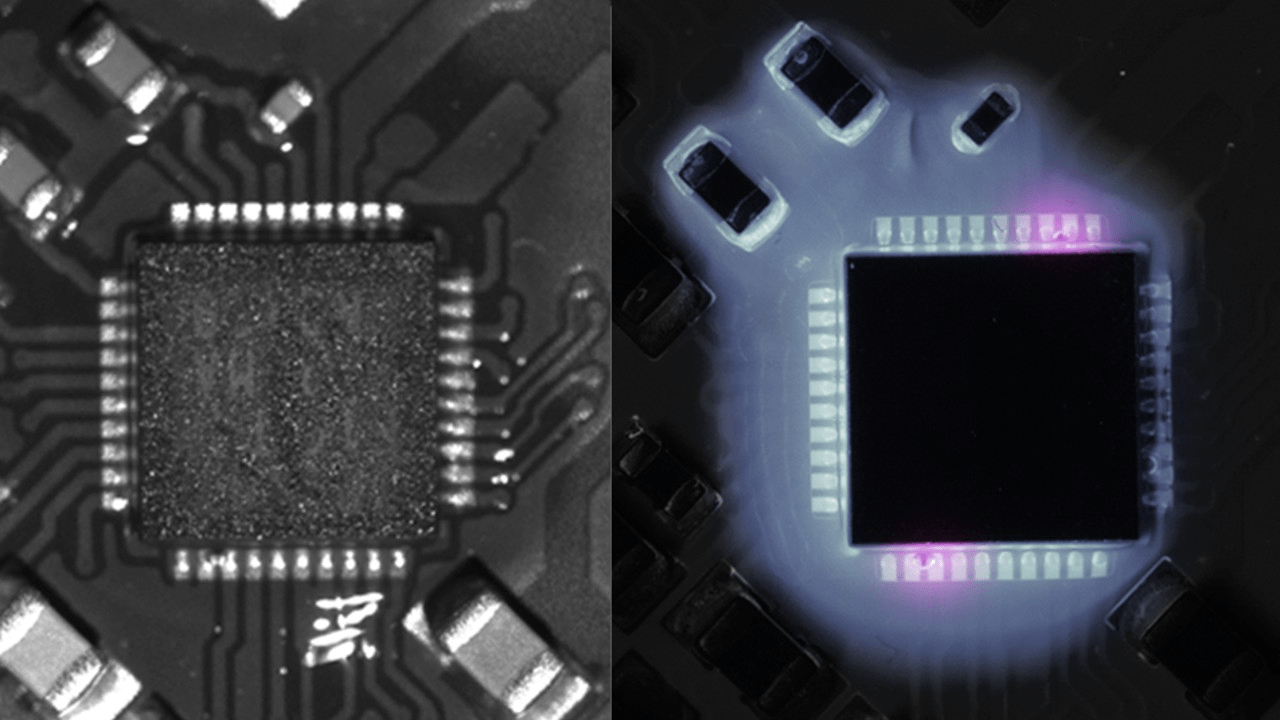

We make the invisible visible

Specialized imaging enables you to optimally record defined product features for every application. In our laboratories we carry out feasibility studies and process development for you, thus ensuring your success at an early stage.

Our innovations create new opportunities

With our innovative modular system of powerful imaging processes and robust algorithms as well as the user-friendly software platforms, we can reliably solve your demanding tasks.

We complement classic image processing methods with artificial intelligence algorithms.

The in-house developed AI Suite enables the expert to incorporate process knowledge into the test system without programming and offers the user a high level of transparency in the test decision.

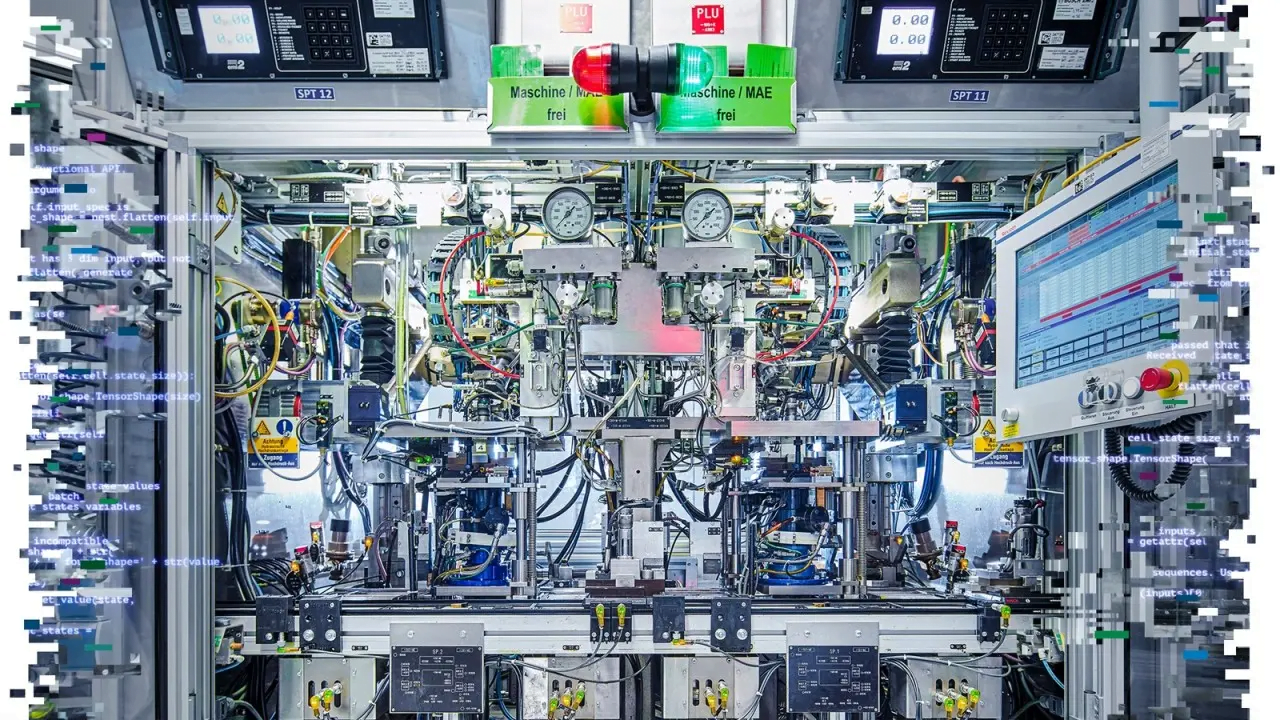

Interdisciplinary engineering is our daily work

Thanks to working closely with our mechanical engineers, we can always implement solutions with high synergy through the interaction of testing technology and parts handling.

We stand for quality, transparency and reliability!

With the implementation of objective proof of ability and acceptance of our solutions according to recognized quality guidelines, we promise that you can operate our technologies in your company with confidence and deliver top quality.

Our Products & Solutions

Our solutions and services are precisely tailored to your requirements. We have made it our business to support our customers with competitive tailor-made concepts. In doing so, we work closely with the Research and Advance Development departments to ensure the continuous development of production technology.

Advice & Feasibility Studies

We would be happy to advise you on the definition of suitable test criteria and test concepts. With feasibility studies, we secure the later project success for you at an early stage.

Machines & Systems

We offer you an optimal system of imaging, process control and algorithms for the inspection task and support you with the integration into your machine. In addition, if required, we can develop precise parts handling through to complete machines.

Service & Training

Through the targeted training of your employees, we enable you to optimally operate our solutions. Our HelpDesk is at your side. We adapt the machine vision systems and solutions to the needs of your production by optimizing and expanding them.

GET IN TOUCH

QREATIQ DIGITAL LLC

#14-01/02, 31B Exeter Road, Comcentre Tower

One Raffles Quay (ORQ). Central Business District (CBD)

Singapore 239732

E:[email protected]

P:+65 6848 4488

F:+65 6848 4466

The in-house developed AI Suite enables the simple use and integration of AI solutions in image processing applications without any special prior knowledge in the field of artificial intelligence.

- Innovations of the AI community are tested and continuously integrated into the platform

- Decisions of the AI solutions are presented to the user in a transparent and visually understandable way

- Labeling of the image data as well as training and verification of the AI network are carried out separately from the inspection system in the office

- The process knowledge of the experts flows into the test decision without programming

- Cost and time reduction through machine learning of the features on classified images

- Solving visual inspection tasks that could previously only be carried out manually

- Simple use of AI through user-friendly operating concepts and without software development

- Integrated in our image processing platforms

XPIX

XPIX