CASE STUDY

The request we received was to produce an automatic system which would guarantee safety, reliability, ductility, simplicity at a low cost. The end Customers were located worldwide, and therefore a great deal of attention has been paid during the design phase in order to ensure the necessary requirements.The final solution should therefore live up to the constant technological growth and produce the lowest possible post-sale impact.

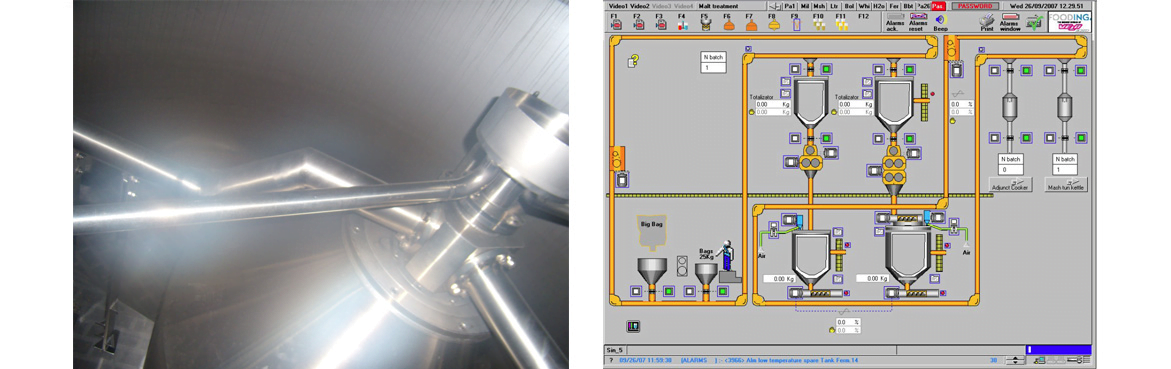

The automated system was designed starting from the experience gained in the sector, by applying concepts and patterns conceived by the Technologist and building a synergic relationship with PT Multi Bintang Indonesia. Special care was paid to reference standards, environmental and usage conditions when designing the hardware.The technological process was broken down to its minimum components in order to develop algorithms which would allow on the one hand to reduce costs by eliminating unnecessary hardware components, and on the other to ensure accuracy and speed of reaction by immediately identifying the critical points of the system.

The automated process was tested in our offices in the presence of PT Multi Bintang Indonesia and of the end Customer, simulating actions and reactions and granting the users the actual view of the finished product even before the start-up.

• the careful design from the smallest detail to its overview;

• the end Customer’s participation in the project thanks to the possibility of simulating actions/reactions;

• the creation of the recipes prior to start-up starting from technological values;

• the considerable precision adjustments guaranteed by the functions and formulas put forward theoretically;

• the possibility of quick changes and actions thanks also to the large and detailed supporting documentation.

• the success of the operation was represented by the satisfaction of both PT Multi Bintang Indonesia and the end Customer.