Rebuilding Automation Services

CUSTOMER REQUIREMENTS

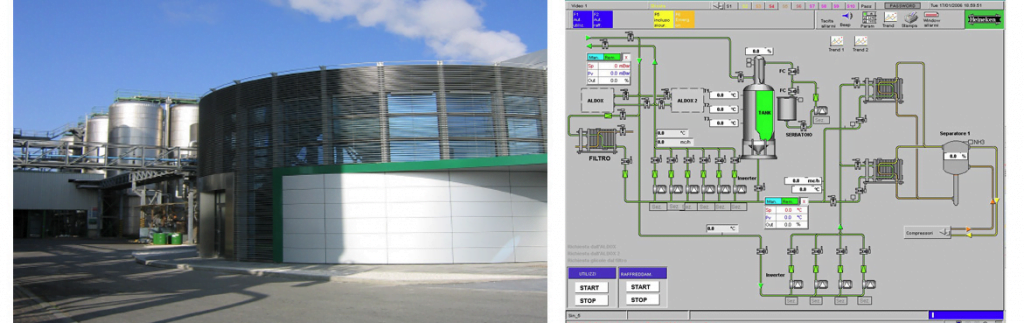

To perform the software revamping of the entire service sector of the plant in order to standardise processes and controls as well as the graphic interface without impacting on normal production activities.

Contextually to the revamping, the need arose to implement plant areas which were still ‘invisible’ at a synoptic and data level.

THE SOLUTIONS

In order to solve this problem we organised various operations designed to test every zone in detail for each area involved by the revamping software.

The task required an high level of coordination so we created a team with different skills.

Our presence at the customer’s site was necessary in order to collect as much information as possible, thus reconstructing the history of the various systems and identifying the critical points. On this basis we began designing the new software which, piece by piece, was tested directly in the production cycle of the Plant.

Then we developed the stand-alone software parts which allowed immediately an effective operation when it is combined, without stopping the production cycle.

THE RESULT ACHIEVED

The start-up occurred without causing any problems to the production cycle.

The customer was able to schedule and organise the time intervals reserved for testing, thus avoiding any production problems.

The operators of the various departments immediately mastered the new system thanks to the progress in small stages tested during the period prior to the start-up.

It was possible to deal with data hitherto untreatable thanks to the use of a Database extended to every analogue signal.

KEYS TO SUCCESS

The ability to analyse and apply the best strategy starting from existing conditions.